关于Polymaker

Polymaker大事纪

产品时间轴

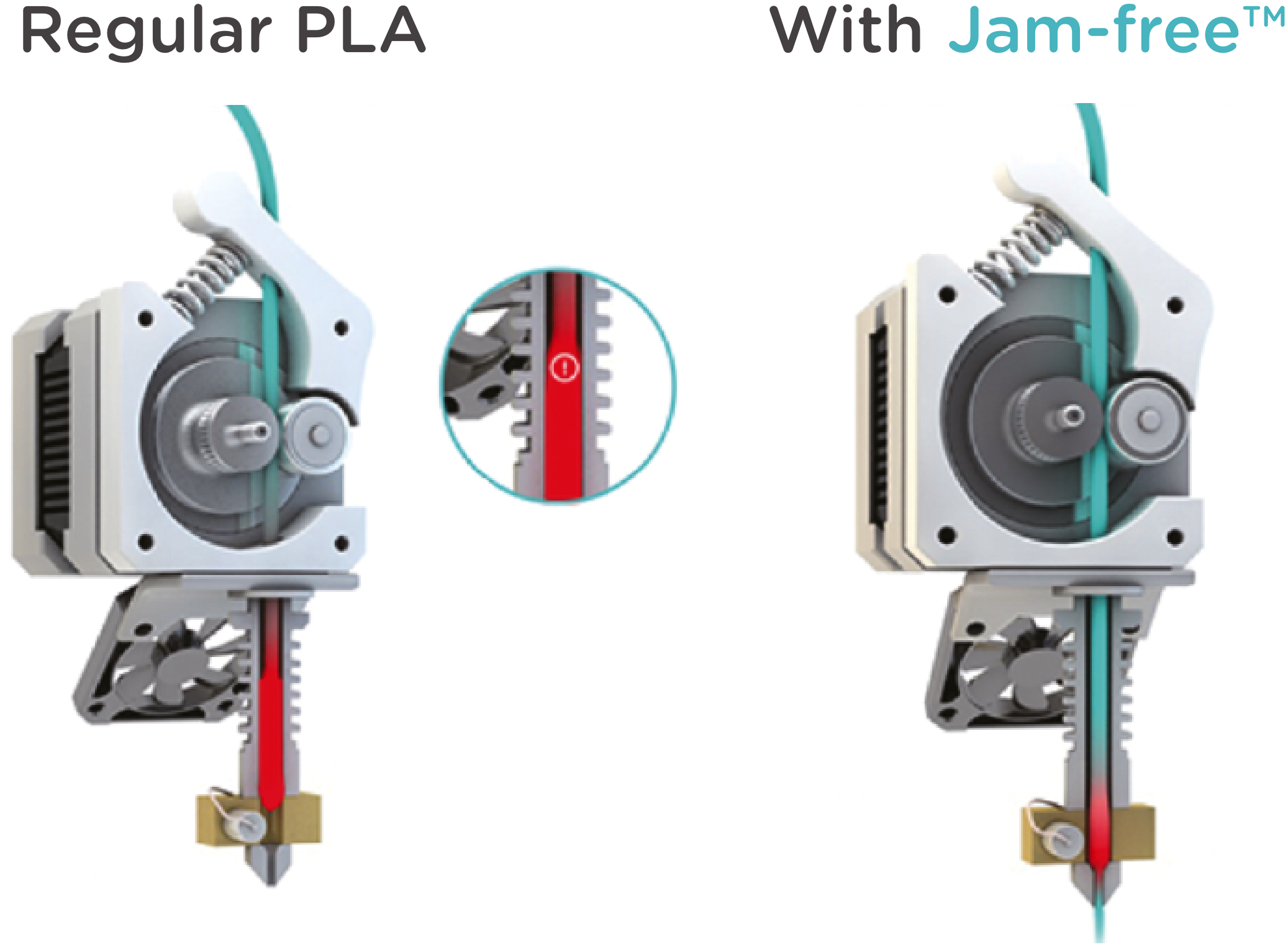

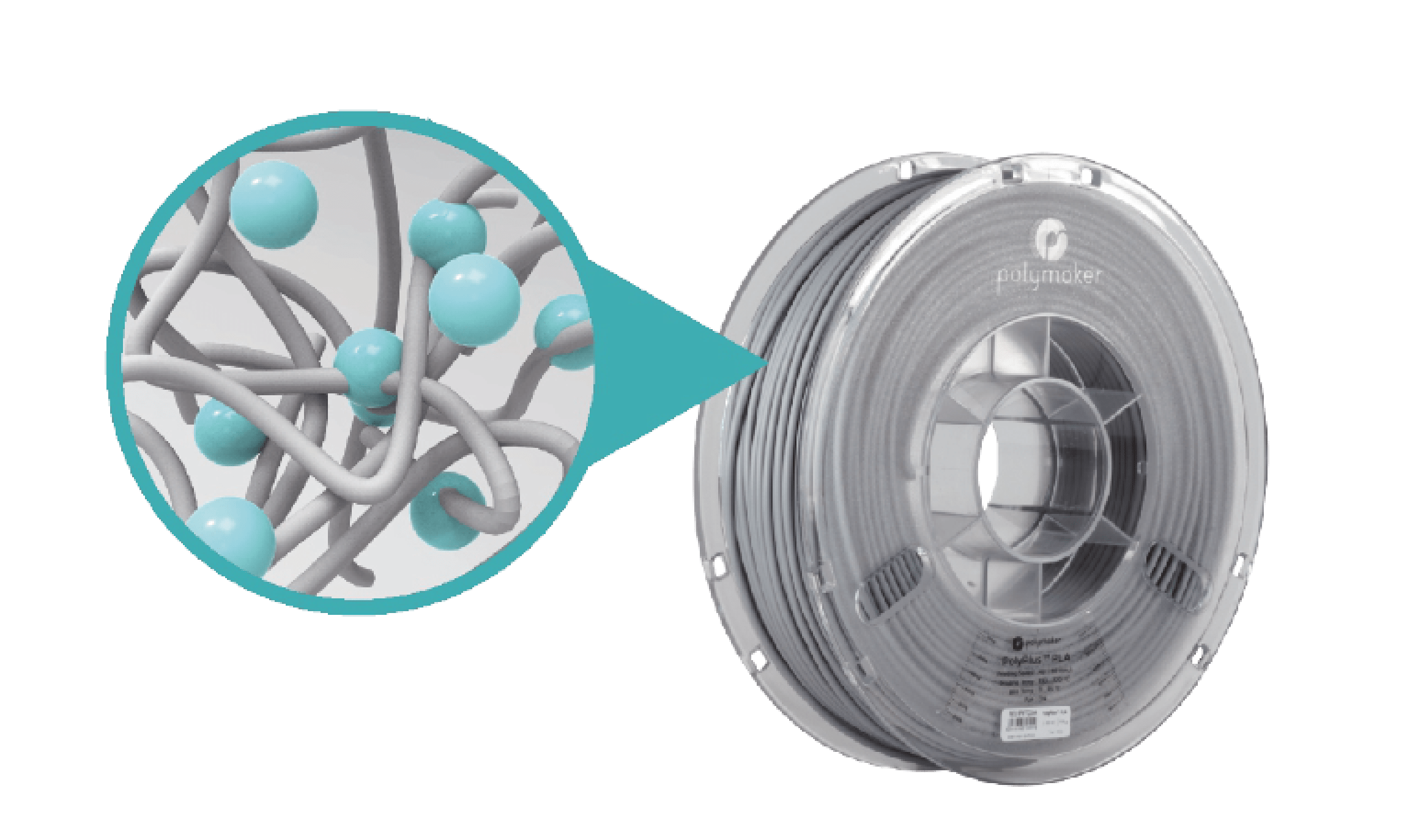

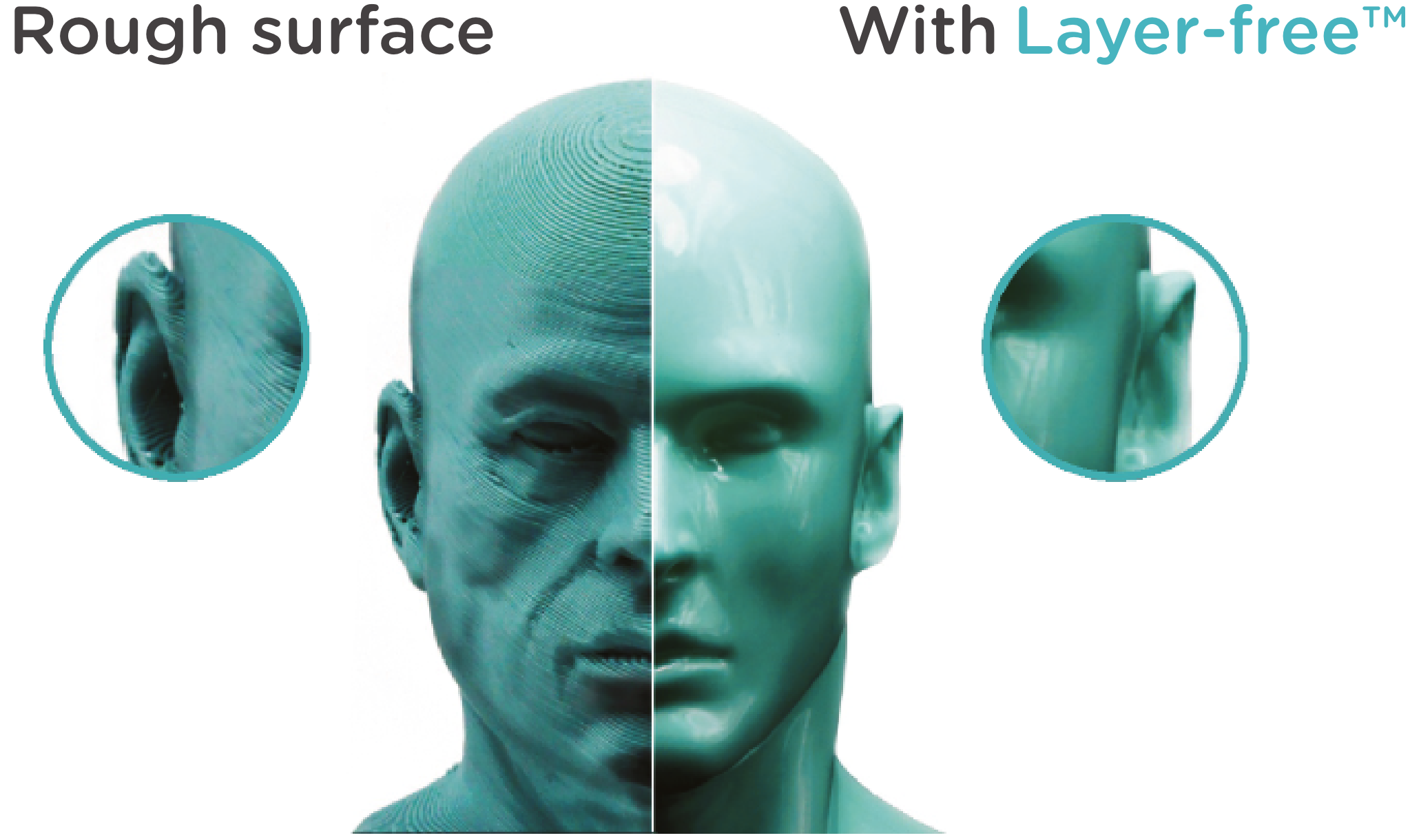

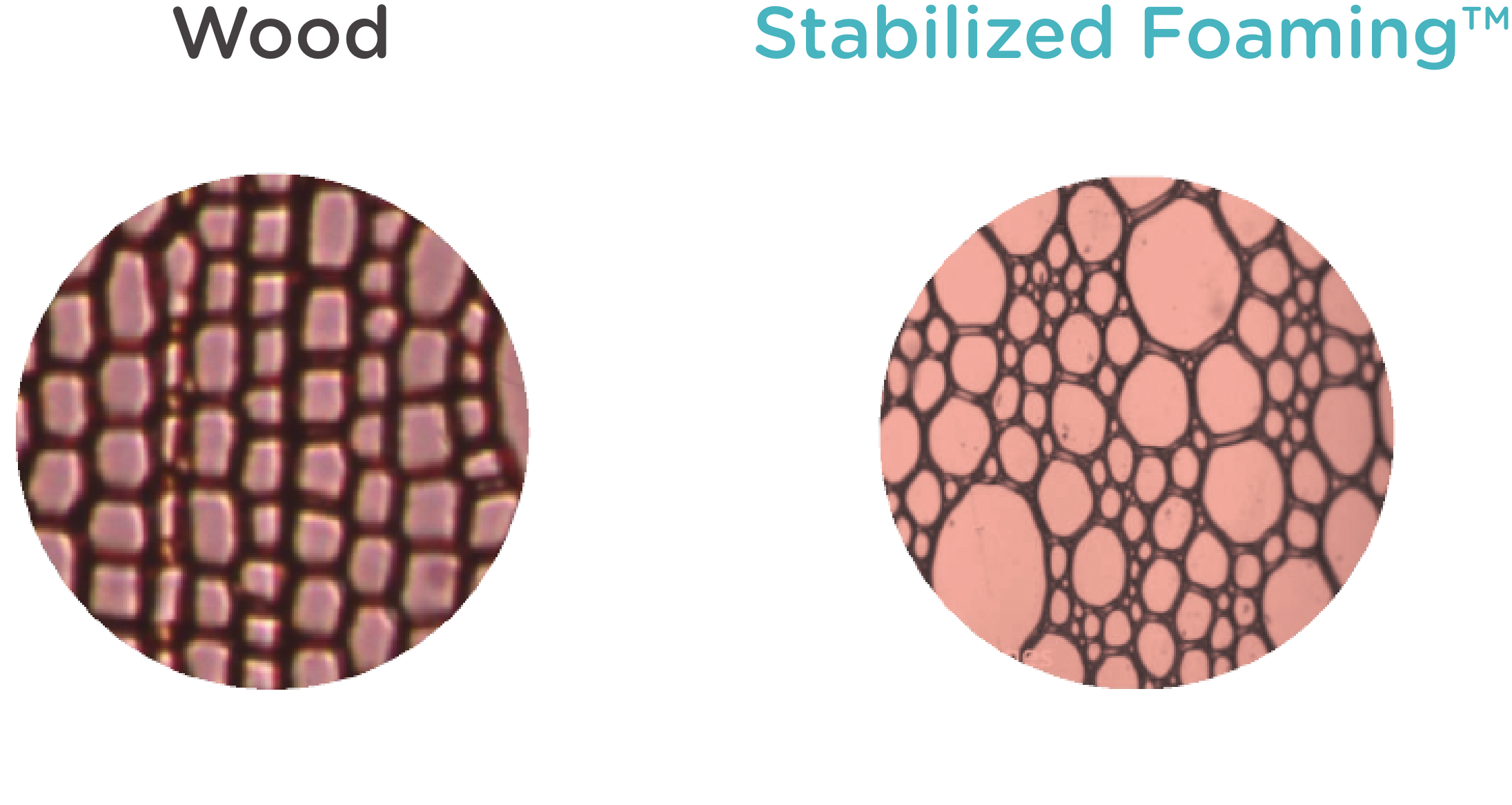

Key Technologies Developed by Polymaker

Polymaker开创了多项前沿专利和技术

About Polymaker Industrial

Polymaker Industrial is a series of engineering grade material solutions developed for the industrial 3D printing sector. Offering full customization of polymer compounds, Polymaker’s R&D scientists can tailor material characteristics to match your applications. Polymaker Industrial has an ever-growing portfolio of materials which enables customers to respond quickly to market needs. This includes offering small batch customized production and high-quality material solutions for high-temperature applications, flame retardancy, bio-compatibility, ESD and investment casting & moldings.

服务与支持

如果对我们产品有任何问题,可到支持中心寻找解答,也可随时与我们邮件联系。 inquiry@polymaker.com.cn.

服务全球100+地区的企业及个人用户,挤出式3D打印材料信任之选

Polymaker办公地点

常熟,中国

上海,中国

乌特勒支,荷兰

休斯顿,美国